GGM 400 Gas Membrane

Loose laid sheet membrane system designed to protect buildings against the ingress of methane, radon, carbon dioxide, hydrocarbon vapours and water vapour

Product Description

GGM 400 Gas Membrane is a high performance, reinforced polyethylene membrane incorporating a gas resistant aluminium foil. The multi-layered laminate structure gives good strength, flexibility and installation properties. The upper surface of the membrane is coloured green. When used with other components in the GGM 400 Gas Membrane System, a high performance gas protection system can be installed to prevent harmful gases and vapours from entering buildings. GGM 400 Gas Membrane also functions as a damp proof membrane and may be linked with other membrane systems to form a fully engineered, continuous, water and gas resistant solution for deeper structures

Applications

- Sites with medium to high level gas concentrations

- Sites with low to medium level hydrocarbon vapour contamination

- Ground bearing concrete slabs

- Suspended concrete slabs

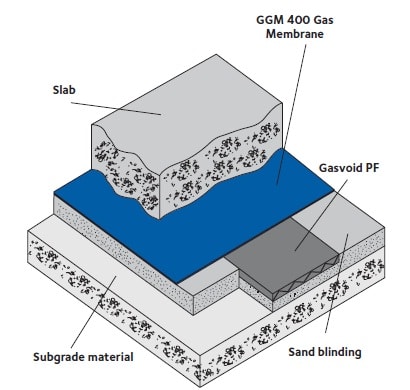

System Components

- GGM 400 Gas Membrane

- GGM 400 Tape – butyl tape for sealing laps

- Bituthene® MRX* – self adhesive gas resistant membrane

- Servipak® Board* – 3 mm bituminous protection board

- GGM Gasvoid PF – venting geo-composite for partial footprint venting

- GGM Gasvoid FF – venting geo-composite for full footprint venting

- Venting system components – for venting at building perimeters

- Protection Roll – 2 mm bituminous protection roll (special order)

For combined gas protection and waterproofing applications, the following additional GCP products may also be used:

- Preprufe® 300R / 160R Plus* – pre installed waterproof and gas resistant membrane

- Bituthene® 800PA* – self adhesive waterproof and gas resistant membrane

* see separate datasheets for product and ancillary details

| SUPPLY AND STORAGE | |

|---|---|

| Product | Unit Size |

| GGM 400 Gas Membrane | 2 m x 50 m rolls |

| GGM 400 Tape | 50 mm x 15 m rolls |

| Servipak Board 3 mm | 1 m x 1.5 m boards |

| GGM Gasvoid PF/FF | 0.92 m x 50 m rolls |

| Preprufe 300R/160R Plus | 1.17 m x 30/35 m rolls |

| Bituthene 800PA | 1.2 m x 35 m rolls |

| Bituthene MRX | 1 m x 20 m rolls |

| Venting System Components | Each (various sizes) |

| Protection Roll 2 mm | 1 m x 20 m rolls |

Store all products unopened in original packaging in cool, dry conditions out of direct sunlight. Shelf life in these conditions is 12 months from date of manufacture.

| TECHNICAL DATA | |

|---|---|

| Typical Value | |

| Thickness | 400 μm |

| Weight | 360 g/m2 |

| Tensile Strength | >9 kN/m |

| Tear Resistance | >350 N |

| Moisture Vapour Transmission | <0.03 g/m2/day |

| Radon Transmittance | <1×10-9 m/s |

| Methane Transmission | <0.005 ml/ m2/h/atm |

Note: All test results shown in this data sheet are determined under laboratory conditions, using product samples taken from inventory in original packaging, without alteration or modification.

Product Advantages

- Fully compatible with GCP Preprufe® and Bituthene® membrane systems to form an integrated waterproof and gas resistant protection system

- Prevents the transmission of methane, radon and carbon dioxide gases

- Resistant to hydrocarbon vapours

- Fully bonded lap system

- Robust – resistant to on-site damage

- Good puncture resistance

- High tear and tensile strength

- Flexible – can accommodate normal building movements

- Weldable

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact GCP Technical Services.

Application

Surface Preparation:

Suitable substrates include concrete, venting geocomposite, insulation, sand or other well consolidated aggregate. Where aggregate cannot be compacted to provide a smooth closed surface, a further blinding of sand or other fine aggregate should be applied. Remove any sharp protrusions that could puncture the membrane and ensure surfaces are well consolidated.

Membrane Installation:

- GGM 400 Gas Membrane can be installed above or below ground bearing slabs.

- Where GGM Gasvoid PF or FF is used, lay the membrane directly onto the Gasvoid product.

- Minimum lap width is 150 mm, seal all laps by taping with GGM 400 tape or using heat welding equipment.

- Any membrane integrity testing should be carried out before installation of protection boards or screed.

- For above slab installations, temporary or permanent protection against site damage should be provided with 3 mm Servipak 03 boards, Protection Roll or a minimum 50 mm screed.

Penetrations:

All pipe entries, stanchion bases, columns and other penetrations through GGM 400 Gas Membrane should be sealed as per typical details.

Lift Pits, Service Ducts etc:

All vertical and inclined concrete and masonry surfaces should be primed with Preprufe SC1 primer, prior to the application of Preprufe 800PA self adhesive gas resistant membrane.

NBS Specification Clause

Clauses: J40/140, J40/145

Product reference: GGM 400 Gas Membrane Manufacturer: GCP Applied Technologies, Ipswich Road, Slough, Berks, SL1 4EQ or gcpat.com

Health and Safety

Before using any of the products included in this product data sheet, read the product labels and comply with all health and safety advice.

Users must comply with all risk and safety phrases. SDS’s can be obtained from GCP Applied Technologies or from our web site at gcpat.com.